General information

Dear customers,

We would like to introduce our new line of mixers for mortar, stucco, grout, adhesives, penetrations, paints and other materials of similar consistency. We have just launched this new line of products and are very confident that you will be able to find the right product that meets your needs and expectations.

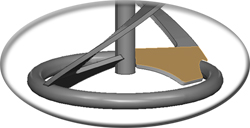

In total, there are about sixty types of mixers available under the ENCO-MIX brand, which guarantees a superior quality and performance. There are divided into three standard sizes with diameters of 80, 100 and 120 mm. Each size is available with two, three or four mixing spirals, which come in regular or extended version, and all types can be supplied with clockwise or counter-clockwise spiral agitator *. All mixing paddles have a steel ring at the end, preventing the spirals from hitting the container in which the material is being mixed. The spirals are designed to pick up the mixed material from the very bottom of the container without the risk of damaging it, as they do not extend beyond the steel ring (see picture below). In standard version, the stirrers come in a black surface finish only **. For higher-volume orders, it is possible to have them made with galvanized or powder-coated (classic Komaxit) finish in a shade of your choice.

Stirrers with a diameter of 80 mm (length 500 mm) are manufactured with an 8 mm hexagon and are designed for use with a conventional drill chuck ***.

Stirrers with a diameter of 100 mm (length 600 mm) are manufactured in a version with an 8 mm hexagon for classic drill chucks, and also in a version for SDS+ fastening.

Stirrers with a diameter of 120 mm (length 600 mm) are manufactured with M14 thread for use with mixing machines, and also with SDS+ fastening.

Due to a large number of possible variants of these stirrers, we only keep 40 basic types in stock (see links under the main menu). If you are interested in some of the other types, we will be happy to manufacture them for you based on your requirements.

* Clockwise spirals "pull" the material from the bottom to the surface while rotating clockwise, and counter-clockwise spirals “push” it from the surface to the bottom in the same direction of rotation. In general, clockwise spirals are more suitable for mixing thicker and stiffer materials (stucco, construction adhesives, concrete screeds, etc.), and counter-clockwise spirals for mixing thinner consistency (penetrations, paints, thin self-levelling compounds, etc.).

** With this surface treatment, it is guaranteed that the surface color coating will not peel off into the mixed mixture.

*** If you are interested, it is also possible to make stirrers with a diameter of 80 mm to order in the version with SDS+ clamping.